Automating a welder improved Abecca’s productivity

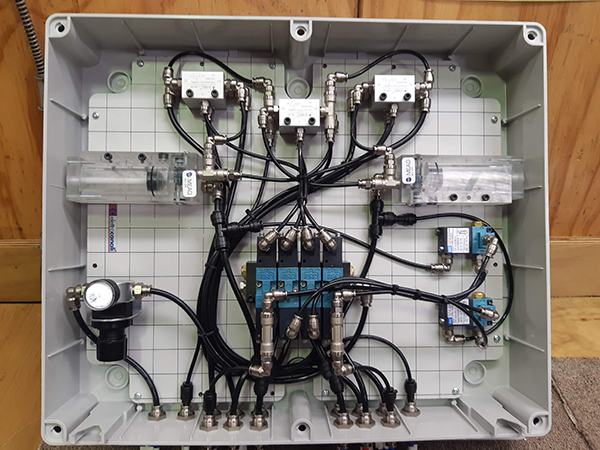

Abecca’s staff now work more efficiently, thanks to Compressed Air Controls automating a welder.

“Automating our High-Frequency welder sped up the production flow immensely as it means the operator can work on another job while waiting for the product to go through the welding process,” Abecca General Manager Joseph Beatson said.

The High-Frequency welder uses radio frequency waves combined with pressure to create strong, leak-proof seams on their safe furniture that has been designed and developed specifically for the use of clients with behavioural problems and unpredictable tendencies. The company also manufactures positioning supports, including positioning supports for radiology treatments.

Compressed Air Controls also changed the welder from a sit down to a stand-up machine so that the machine operator can easily move between machines and operations.

“We place our welders back-to-back so one single operator can do two operations, leading to minimal downtime while the operator is waiting for the weld to go through its cycle.”

Contact Compressed Air Controls Ltd now to see how automation could improve your productivity.