Compressed Air Controls supply air compressor accessories

Compressed Air Controls supply air accessories and can design your air compressor setup. We can also install these accessories and repair and maintain them. We can also retrofit some accessories, like air dryers and Variable Frequency Drives (VFD/VSD).

These accessories include ELGi:

- Variable Frequency Drives (VFD/VSD)

- Air receivers

- Air dryers

- Filters

- Oil-water separators

- ELGi’s Heat Recovery System

Compressed Air Controls also supply Donaldson drains.

Why do you need air compressor accessories for your industrial air compressor?

Otherwise, your compressor could choke on contaminants and break down frequently and also have a shorter life.

Contaminated air could negatively affect the product you are producing as well. If contaminated air is used to spray paint a car, for example, then the paint could end up with fine particles in it.

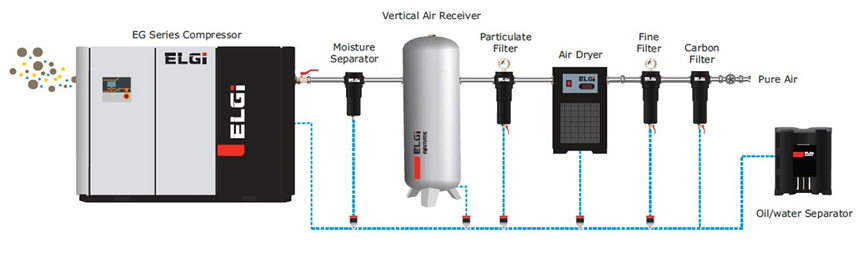

Compressed Air Controls follows best practice for removing contaminants from compressed air by supplying air accessories

We will provide the correct sized moisture separators, so that maximum bulk moisture is removed from the system and is not carried over to the downstream equipment.

We will also provide the correct coalescing filter type, rating, size, and appropriate preceding level for the selected filters. We will also replace the filter element at proper service intervals.

We can supply electronic drains. These play an important role in removing the condensate from the compressor and downstream equipment. We will properly maintain and replace the electronic drain regularly, as per recommendations.

Air dryers and filters are a must. An air dryer should be in front of the fine filter and carbon filter so that the compressed air is free from water vapour. This is critical, as the vapour can choke the filter element. A particulate filter is recommended after the desiccant dryer and before the fine and carbon filter.

If your site needs more stringent air quality, we will recommend having an additional desiccant dryer, which will give a lower dew point, and filter set near the point of use.

Why do you need air dryers for your air compressor?

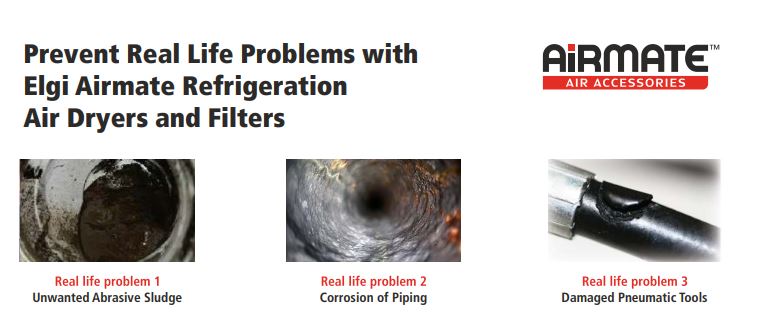

ELGi refrigerant and desiccant dryers prevent moisture from humid air corroding the air piping and washing out pneumatic tools' lubricating oils which can cause them to work inefficiently. If a pneumatic cylinder is provided with dry compressed air then it will last 10 times longer.

How do compressed air dryers work?

EGRD Refrigerant air dryer

EGRD Refrigerant air dryer

The hot high-pressure refrigerant enters into the condenser in a gaseous state and gets cooled through the forced circulation of cold air using a fan and flows to the expansion valve in a liquid state.

Three reasons why you should invest in a refrigerant air dryer

1) It is reliable.

2) It is great for demanding applications.

3) It is eco-friendly as it uses ozone-friendly R 134 A and R 407 C refrigerants for minimal impact on the environment.

What industries does a refrigerant dryer suit?

These dryer types are ideal for manufacturing operations where some degree of retained moisture (ISO Quality Classes 4, 5 and 6) is acceptable.

These air dryers are typically operated at higher dew points than desiccant dryers.

Refrigerated air dryers also have a lower overall cost of purchase, operation, and maintenance when compared to a desiccant dryer.

Desiccant air dryer

Desiccant air dryer

This granular desiccant bed in the first tower absorbs moisture from the air. The second tower takes the dry purge air from the outlet of tower one and feeds it through a purge valve to regenerate the granular desiccant bed.

As a default, all HLD models above 5X are provided with a Dew Point Stretch Cycle and Purge Optimizer.

Why you should invest in a desiccant air dryer

1) A Purge Optimizer saves you money

You can save money on your air compressor's energy usage through the use of a dew point sensor and controller and get a return on investment in 3 to 6 months. Read how it has benefitted Foodflo International Ltd.

2) A desiccant air dryer can handle hot and cold rooms

These dryers can handle the heat- they can be installed anywhere as they handle any ambient temperature, including boiler rooms. They can also handle cold temperatures like chilled rooms.

What industries does a desiccant dryer suit?

They are suitable for industrial drying applications where dry air is required like metal finishing and the food and beverage industry because water vapour in compressed air passed through a desiccant dryer is more thoroughly eliminated than any other drying method.

Desiccant dryers operate at significantly lower dew points which facilitates the elimination of moisture more efficiently than a refrigerated dryer.

Why are desiccant air dryers needed for contact applications like food and beverage processing?

In short: desiccant air dryers are needed to make sure there is no moisture in the compressed air that can spoil food by contaminating it or damage packaging, as they purify the air to a lower dew point which ensures that the air is as dry as possible.

Compressed air is used in the production of food and beverages, as well as during the bottling, packaging, keg washing and transportation of those so that compressed air must be moisture and contaminant-free to ensure the protection of the food products.

Compressed air is used in the production of food and beverages, as well as during the bottling, packaging, keg washing and transportation of those so that compressed air must be moisture and contaminant-free to ensure the protection of the food products.

When an air compressor pulls in ambient air to compress it, it also pulls in all the humidity and particulates that are floating around in the air. Those liquids, vapours and solids can cause issues downstream, which is why you use filters and air dryers.

Air filters prevent particles and contaminants from ruining the final product.

Air dryers prevent humidity and condensate from getting into the ingredients, packaging and products. This also prevents any equipment that uses compressed air from becoming clogged or rusted over time because of condensate.

ELGi Filters

The Alocrom aluminium treatment is a special feature of all ELGi Airmate die-cast filter housings. This treatment ensures there is no corrosion and no carryover of corroded particles into the airline, which can otherwise cause blockades in sophisticated parts.

TYPE PF

High-efficiency General Purpose Protection.

For the removal of particles down to 1 micron including coalesced liquid water and oil, providing a maximum remaining oil aerosol content 3 of 0.5 mg/m @ 21ºC

TYPE FF

High-Efficiency Oil Removal Filtration.

For the removal of particles down to 0.01 micron including water and oil aerosols, providing a maximum remaining oil aerosol content of 0.01 mg/m @ 21ºC. (Precede type FF with type PF)

TYPE CF

Activated Carbon Filtration.

For the removal of oil vapour and hydrocarbon odour giving a maximum remaining oil content 3 of <0.003 mg/m (<0.003 ppm) (excluding methane) @ 21ºC. (Precede type CF with type FF & PF)

Donaldson UFM-D drains

Donaldson UFM-D drains

These offer silent operation, fast return on investment and a low maintenance option to handling the liquid condensate, which naturally accumulates in various spots within a compressed air system.

Condensate must be drained frequently, and typical drains are prone to loss of valuable compressed air. The UFM-D drains offer the ability to silently and cost-effectively drain condensate from your compressed air system.

Features

- Electronically level-controlled minimizes loss of costly compressed air

- Easy service with all maintenance parts in a single unit

- Manufactured with corrosion-resistant materials

- Silent operation

Applications

- Air compressor aftercoolers

- Air receivers

- Coarse coalescing prefilters before refrigerated and desiccant dryers

- Fine coalescing prefilters after refrigerated and desiccant dryers

- Refrigerated dryer cold-points or outlets

- Desiccant dryer outlet

ELGi Air Receivers

ELGi Air Receivers

The ElGi Air Receiver is engineered to handle the stress of fluctuating air demands, reduce wear and tear and increase the life of the end-use equipment.

What are the benefits of air receivers?

Stored Energy: The primary role of an air receiver tank is to provide temporary storage for compressed air. It stores compressed air that can be used for short spikes in demand, also referred to as ‘events of sudden demand’. It also acts as a standby supply system, when tricky situations may arise at a factory including, power outage for a short period (typically switching from a grid to generator), a sudden unplanned loss of supply from a compressor (typically from breakdown), etc. Think of the importance of a battery with UPS supplying power for a computer to function without disruptions, the air receiver is that reliable battery source which enables smooth functioning of your business.

Stabilizer: Fluctuating compressed air utilization causes uneven demand on the air compressor, resulting in rapid cycling of the air compressor controls as the air compressor turns on and off to meet moment-by-moment demand.

Each time the system turns on and off (or loads/unloads) it is called a “cycle.” It is better for the air compressor motor and other components to keep these cycles as long as possible. This is true for all upstream equipment like dryers, particle filters etc. The stabilized flow through these systems allows the equipment to function to its intended performance.

Improves Efficiency for Air Compressors: As the air compressor cycles on and off, compressed air can be wasted. Every time a rotary screw air compressor cycles to unload, the Separator tank is blown-off from its operating pressure typically from 7 bar to near atmospheric pressure. Compressed air is released during the venting.

With cycling once every few seconds (typically under a minute) this adds up to the loss of a sizeable percentage.

Improves Efficiency for Dryers: If used as a wet tank (or receiver before the dryer) the receiver acts as a heat exchanger, cooling off the air and thus condensing some moisture before it reaches the dryer. The water drains out of a valve at the bottom of the tank. By removing some moisture in advance, the air receiver tank reduces the amount of work the air dryer needs to do. This is true for any dryer type from refrigerated air dryer to desiccant dryers.

Improves efficiency for Coalescing filters: The moisture removal to some extent allows the filters to be relatively dry, in comparison to the direct handling of compressed air coming from the compressor, for the same reason as mentioned above.

There are two types of compressed air storage: wet and dry.

The tanks are the same; the difference is in where they are installed within the system.

Wet receiver tanks are located before the compressed air dryer. Some functions of the wet receiver include:

- Isolating the compressor from demand events

- Reduces/eliminates compressor cycling

- Allows the compressor to remain unloaded for a longer time

- Acts as a backup for compressor failure

Dry receiver tanks are located after the air dryers, to store compressed air that has already been dried to its desired level of the application.

- Dry compressed air is available closer to the application and is hence available in the case of a high-demand event or supply failure.

- Dry storage reduces the burden on the air dryer during high-demand events. Without a dry air receiver (but having a wet receiver only), during sudden spikes in demand, the dryer can be subject to higher volumes than the dryer is designed/rated for. This leads to lower drying efficiency and may also result in sudden pressure drops, leading to unwanted water in the air lines and the application desiring of pressure.

It is recommended that the dry receiver is larger than the wet receiver by 2 to 3 times to take care of the points mentioned above. Most applications require a combination of wet and dry storage for optimal efficiency and performance.

Contact Compressed Air Controls to discuss what type and size of air receiver is right for you. We can provide expert advice on this and can design your industrial air compressor setup.

What does an Oil-water separator do?

What does an Oil-water separator do?

As the name suggests, it separates condensate from the compressed air.

When the air is compressed through the air compressor, it results in condensate, a mix of water, oil, and dust particles, along with compressed air.

If not treated properly this condensate can have detrimental effects on the environment.

Regulatory bodies for effluent treatment recommend that this condensate should be cleansed before releasing it to the sewage disposal.

ELGi EOS series is specifically designed to maintain less than 10ppm of oil in the condensate before allowing the fluid to pass on to the environment. The multi-level separation process, of super-efficient fibre adsorbent and activated carbon, ensures the contaminant levels are kept well within the statutory requirements.

How to select an oil-water separator to remove the oil from the oil emulsified condensate before discharging it to the sewage:

- Selecting the correct oil-water separator and element is important for removing oil from the condensate within the permissible limits allowed in the region. This is expressed in terms of ppm units. Usually, it is set from 10 to 15ppm.

- It is important to see that the oil-water separator selected is compatible to operate with the compressed air and condensate mixture flowing through the condensate line.

- The ppm level after separation needs to be monitored thoroughly. If the ppm level is above the recommended level, then the element needs to be replaced. Some of the oil-water separators also have a life indicator for elements to ensure ease in identification

How does a Variable Frequency Drives (VFD/VSD) work?

How does a Variable Frequency Drives (VFD/VSD) work?

ELGI Conserve VFD matches output with demand by varying the motor speed and the power consumption reduces in line with the reduction in demand.

What are the benefits of using a Variable Frequency Drive (VFD/VSD)?

A Variable Frequency Drive (VFD/VSD) saves you energy.

It eliminates the frequent load-unload cycle which wastes power.

A fixed speed compressor operates on a load-unload band of at least 10 psi around the working pressure; an ELGI VFD, the compressor can be operated within a band of 2 psi. Since compressors are not operated under higher than working pressure requirements. There is substantial energy saving; for every 2 psi reduction in operating pressure, there is 1% power saving.

In a fixed speed compressor with a Star-Delta starter, starting current is as high as three times the full load current (FLC). With ELGi VFD starting, starting current is equal to the full load current (FLC). This helps to avoid using heavy rated components like fuses, MCCB, cable size, generator rating, isolators etc.

For compressed air systems with fluctuating demand patterns, the return on investment due to power saving will be less than 12 months.

Read more about the ELGi air accessories Compressed Air Controls can supply you by downloading the ELGi air accessories brochure here.

Contact us for advice; we can design air compressor setups, supply, install or retrofit some accessories and maintain all of these products.

Recover heat, save money

ELGi’s Heat Recovery System helps companies recover approximately 96% of the heat generated during the compression process which can then be utilized for heating of air and water. This in turn eliminates additional equipment requirements to heat water or air, thereby reducing CO2 emissions. ELGi offers its Heat Recovery System as an additional gadget with its EG Series compressor. Customers can easily plug the Heat Recovery System to the air compressor and use the heat generated in the air compressor to warm water and air for use in showers and boilers.

Contact Compressed Air Controls to discuss your needs

We will take into account your application, dew point requirements, installation, operation and maintenance cost and the environment that the air dryer will be installed into.