Why air compressor pre-filters need to be regularly serviced

Blocked pre-filters elevate the air compressor's temperature

Blocked pre-filters elevate the air compressor's temperature

Pre-filters need to be serviced regularly and proactively because pollen, insects, dust, leaves, and more contaminants, block them and the resulting restricted airflow elevates the air compressor's temperature.

There is not that big a difference in temperature between your air compressor working or shutting down

The typical running temperature is 75-85 degrees celsius, elevated is 90-100 and the air compressor will shut down at around 110-120.

Regular servicing protects your air compressor

Regular servicing includes replacing prefilters and changing the oil, which we can do with our wide range of service kits and lubricants, and protects your air compressor.

Regularly changing the oil will also prevent degrading oil from damaging your air compressor.

The Service Coordinators will contact you when your servicing is due.

Contact us to discuss our preventative maintenance schedule AirCare✓ which has a no breakdown guarantee*.

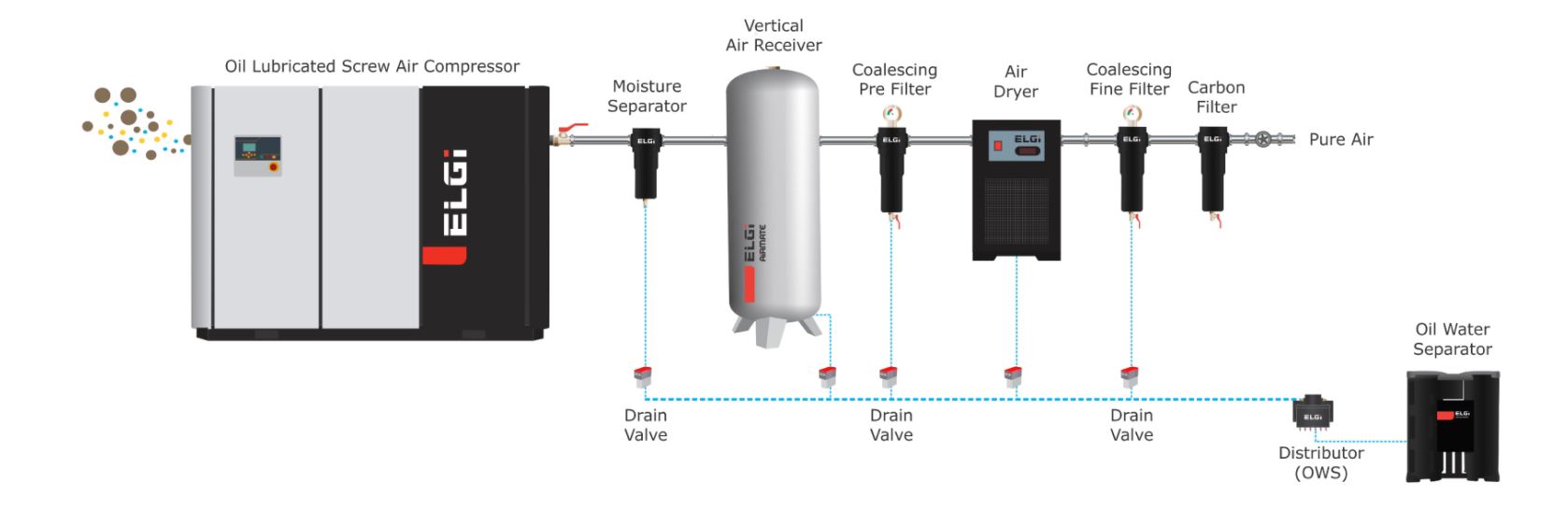

Compressed Air Controls can also design the air compressor setup to proactively protect your air compressor from a dusty environment

Our Territory Managers don't just sell you any air compressor; they visit your site to assess your needs and environment.

They design the air compressor setup to mitigate issues. If the air compressor will be located near a dusty, gravel driveway that lots of trucks use then we would suggest using a screen filter.

We also have accessories that manage the oil's temperature

These include oil coolers and thermostatic mixing valves.