Compressed Air Controls repair and service air compressors and pneumatics and respond to air compressor breakdowns

In orange of the traffic light system:

- Parts: ring or email us and pick those up at the barrier at our front door-please wait behind the barrier, masked up, scan/sign in- or we can courier them out.

- Air compressor or pneumatics brought in for repairs or overhauls: come to the barrier at the front door and we will advise you from there.

- Service Technicians continue with servicing air compressors and responding to air compressor breakdowns, with safety precautions in place. Please keep social distancing and masking up around our Service Technicians. To organise a service, contact our Service Coordinators on 06 929 4640 or planner@aircontrols.co.nz.

Compressed Air Controls Ltd can provide:

- preventative servicing

- reactive servicing- breakdown response

- build and upgrade pneumatic applications

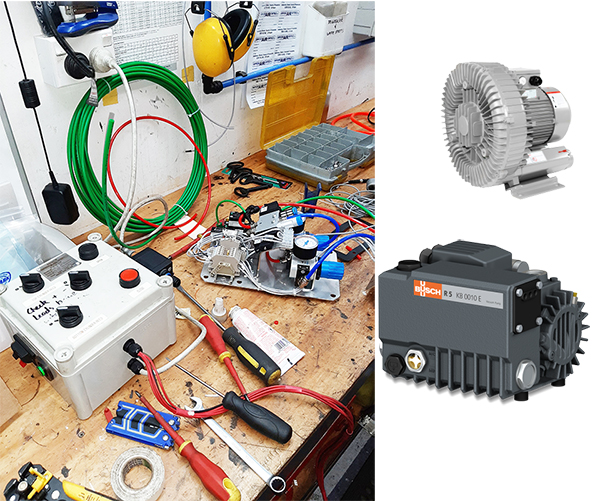

- repair and overhaul air compressors, vacuum pumps, blowers and pneumatics

We service all brands of air compressors and provide quick servicing turnaround and breakdown response

We can provide this because:

- we have seven service technicians across three branches covering the lower North Island

- we have two of the most experienced technicians in the lower North Island

- Those senior technicians have been trained by Kaeser in servicing their air compressors and they have passed that knowledge onto the rest of the service technicians

- the service vehicles are well stocked

- the AirSolve app, exclusive to ELGi distributors, helps technicians solve faults on any brand of compressor quickly

Our Customer Site Management software saves you money

Compressed Air Controls' unique Customer Site Management software tells the Service Coordinators when your servicing is due. They then contact you to find a suitable time to do it.

After the service you are sent a service report.

It also ensures that logistics provide any specific parts right the first time. This saves you money as there are no charges for extra travel time and less production downtime.

The CSM also records all our correspondence about your site.

Consistent, quality servicing and continuity of service and planning

It is our standard practise to ensure two technicians and your territory manager know your sites' servicing needs, costs etc.

We repair air compressors and pneumatics on-site and in our workshops

We can repair your air compressor on-site or you can bring your piston air compressor to our branches for repairs. We will assess your air compressor and advise what the most cost-effective course of action is.

If your air compressor has high hours it can be expensive to maintain so we may suggest replacing it

We have Hindin, Spitfire and ELGi piston air compressors in stock.

We can also overhaul blowers, cylinders, valves, rotary actuators and air tools

Our Service Technicians will assess these and advise what the most cost-effective course of action is; repairing it or replacing it.

If your vacuum pump is playing up you may not have to purchase a new one

We can overhaul it and have it looking and performing like a new machine.

We can repair or supply pneumatic cylinders or have new cylinders manufactured

We have a wide range of cylinders in stock. If the cylinder is a custom-made size we can organise a new one to be machined.

We can also design and build pneumatic applications

These can solve issues like production bottlenecks.

Compressed Air Controls' service guarantee

We have a one-month workmanship guarantee and a three-month parts guarantee on any service work on air compressors.

We provide predictive servicing of air compressors, blowers and vacuum pumps

This includes checking the oil, filters and seals.

Our servicing gives you more value for money

Our servicing includes bearing life monitoring/trending (SPM) and oil analysis, which is unique to us.

We can prevent air compressor breakdowns

Compressed Air Controls Ltd provides predictive maintenance at sturctured levels of Basic, Premium or Premium Plus Cover.

Read more about AirCare✓ and contact your Territory Manager for more information.

Why you shouldn't skip a service:

- Your compressor will not run as efficiently. If the compressor has blocked filters, for example, then the filter can't stop water and contaminants from getting into pipework where it could contaminate your product or downstream equipment, the air compressor will also waste energy fighting the pressure drops. Blocked pre-filters elevate the air compressor's temperature; a change of just 20 degrees can cause your air compressor to shut down.

- Skipping a service could cause damage to the compressor as belts wear out, filters become ineffective and this could cause an expensive breakdown and the loss of production.

- Regular maintenance extends the lifespan of machinery. Checking and replacing the oil and filters can prolong the lifetime of your compressor. Air compressor oil degrades quicker than other machinery's oil.

- The warranty becomes void if your compressor is not serviced according to the manufacturer's recommendations.

- Dirty sites are dangerous. They are fire hazards as debris, like dirty leaves, can clog up your compressor and cause fires. As part of our service, we ensure the air compressor area is clean and free of debris.

- Different seasons create different issues for your air compressor.

We can also provide reactive servicing by responding to air compressor breakdowns

During servicing or a breakdown callout we can provide emergency air through AirHire✓ as we can provide loan air compressors to lessen downtime while repairs are taking place. (We can also provide loan air compressors for short-term projects.)